Grain and ration optimizers

To make sure farmers get the most out of grains and rations with our solutions and to offer a real alternative to soybean and rapeseed cake.

- Improve autonomy

- Improve feed efficiency

- For GMO free proteins

- Reduce occurrences of acidosis

Optimized cereals and rations for protein autonomy and feed efficiency

Dairy cows in production, growing heifers, beef cattle and fattening cattle have high protein requirements. To stay healthy and maintain energy, ruminants must meet their protein needs and achieve a perfectly balanced diet. However, the cost of purchased proteins, such as soybean and rapeseed meal, accounts for nearly 50% of the feeding cost in livestock farming.

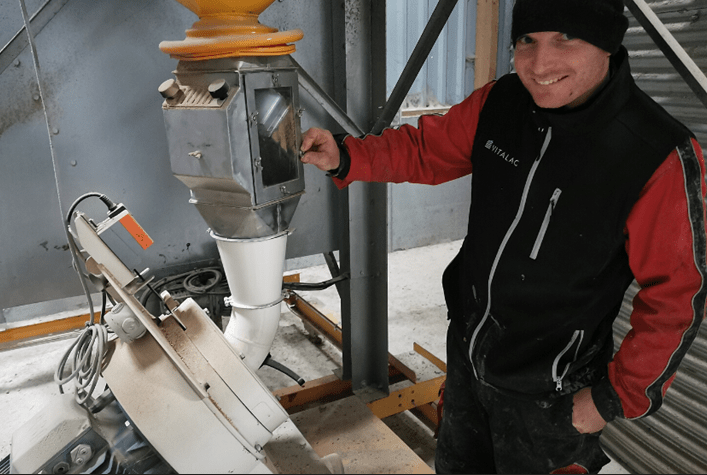

To reduce expenses and ensure sustainable production, farmers need to find a reliable alternative protein source for their animals’ feed. This is why Vitalac has developed a grain optimizer product and a ration optimizer product: XL GRAIN and RUMIX³.

These products are designed to reduce dependency on purchased proteins and optimize farmers’ feed costs by enhancing the value of farmers’ cereals and ration. These specific solutions, designed for ruminants, help farmers achieve protein autonomy and improve feed efficiency while preserving the health of their animals.

Enhanced performance with XL Grain and Rumix³

Cereals optimized by XL Grain or Rumix³ offer many benefits for livestock. First, they help prevent the risk of acidosis, ensuring safe feeding for cows.

Integrating these products into cereals or animals’ ration positively impacts production. In dairy cattle farming, the consumption of optimized cereals and ration improves milk production performance. For fattening cattle, you’ll see enhanced growth performance.

Our solutions promote better digestion and contribute to a more stable rumen pH, leading to improved gut health in animals. Additionally, they help manage feed costs more efficiently, moving towards greater protein autonomy for farms.

Solutions tailored to each species

Dairy cattle

Our grain and ration optimizers

Vitalac has formulated quality optimizers to add value to cereals and dairy cows rations. These solutions have a positive effect on the milk production performance of dairy cattle and on the level of protein intake. Our optimizers ensure safe feeding, preserve the health of livestock and limit the risk of acidosis.

XL GRAIN

RUMIX³

Beef cattle

Our grain and ration optimizers

Beef cattle have high protein requirements. XL Grain and Rumix³ help to boost production performance while maintaining the health of cows and reducing feed costs. Gain autonomy and feed efficiency on farm with our cereals and rations optimizers.

XL GRAIN